Washer repairs

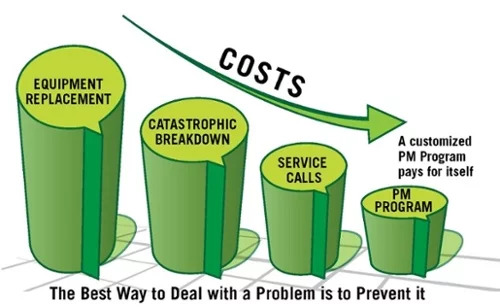

Preventive Maintenance is crucial when operating your commercial washer. Commercial washers have extract speeds that can exceed 400g’s. When a commercial washer is in high extract speed the bearings a re generating heat. Lithium grease has a high melting point and helps keep the main bearings lubricated. Failure to grease the main bearings according to the manufacture specifications can result in premature bearing failure. If the bearings are not greased properly and show signs of heat damage the manufacturer can void the warranty. The average cost to replace the main bearings can exceed $3000.00. A tube of lithium grease is approximately $15.00. Preventive maintenance is priceless!

Dryer repairs

Excessive lint accumulation is the leading cause of dryer fires Ignoring worn or torn lint screens allows lint to accumulate in the dryer exhaust system. This accumulation of lint reduces the diameter of the duct work which causes excessive heat buildup in the laundry room. This dramatically increases drying time and risk of fire. Quarterly preventive maintenance services greatly reduces this risk.

The equipment is designed to be extremely efficient. Having a preventive service program in place will:

- Increase equipment efficiency by returning it back to manufactures design.

- Utility cost savings

- Water usage

- Gas Consumption

- Electrical demands

- Reduce Down Time

SERVICES INCLUDE:

- Extensive and thorough review of commercial laundry equipment.

- Onsite part replacement with approval.

- Early maintenance repair estimates provided.

- Certificate of Completion is posted.